How to reduce costs in metal assemblies?

TAPTITE 2000®

What are assembly costs made up of?

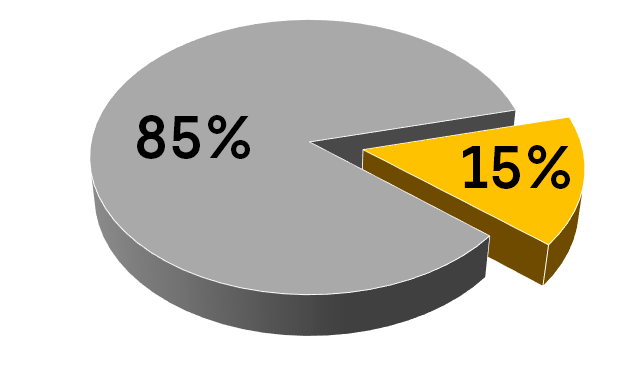

On average, when fastening machine screws in metal assemblies, screw represents only 15% of the total in-place cost. The remaining 85% corresponds to tapping operations, cleaning oil and chips, usage of additional elements to prevent vibration loosening and cross-threading, labor expenses, ...

All of these elements are known as "BIG 85™".

Buying cheaper screws will not save you a lot. Screws represent just 15% of the total cost. The challenge is to reduce this "BIG 85™" and TAPTITE 2000® screw is the best solution to achieve this goal.

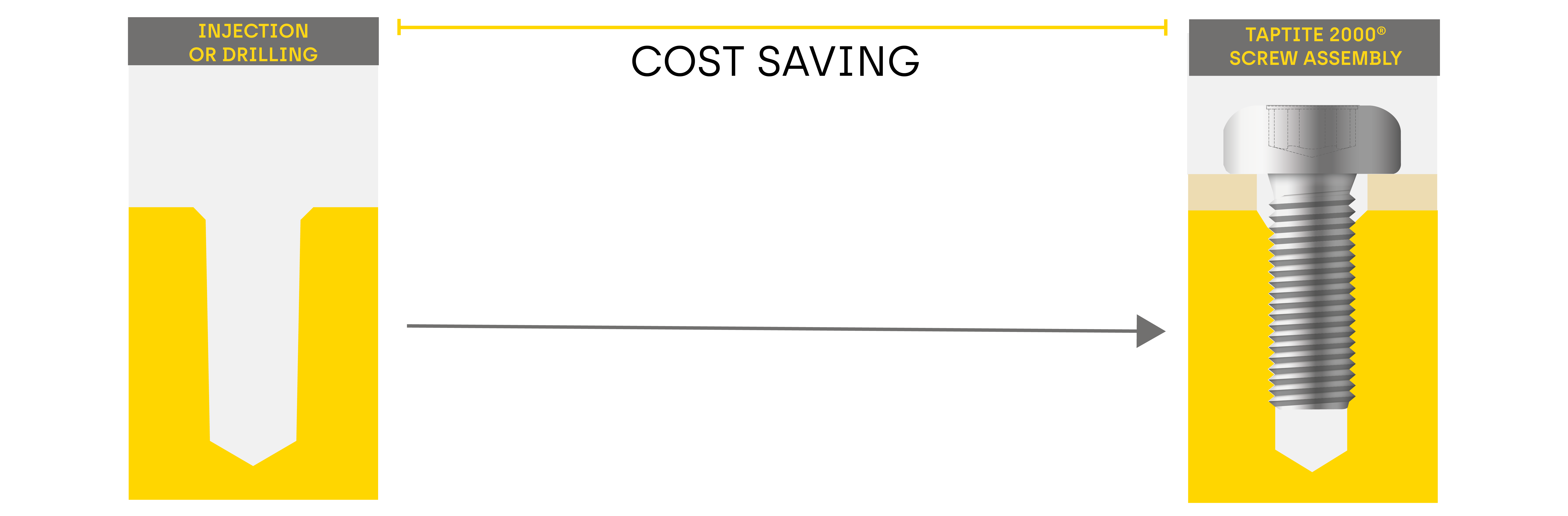

How to save costs with TAPTITE 2000® screw?

TAPTITE 2000® thread forming screws provide assemblies with excellent mechanical properties and ergonomics as well as significant cost savings in the overall assembly cost, that's "BIG 85™":

- Eliminate tapping operation and all associated costs (taps, gauges, cleaning, inspection, ...)

- Eliminate the use of additional elements to prevent cross-threading

- Eliminate the use of additional locking elements to prevent vibrational loosening (adhesive patches, washers...)

Contact us and start saving costs as soon as possible!

Save costs nowContact us and start saving costs as soon as possible!

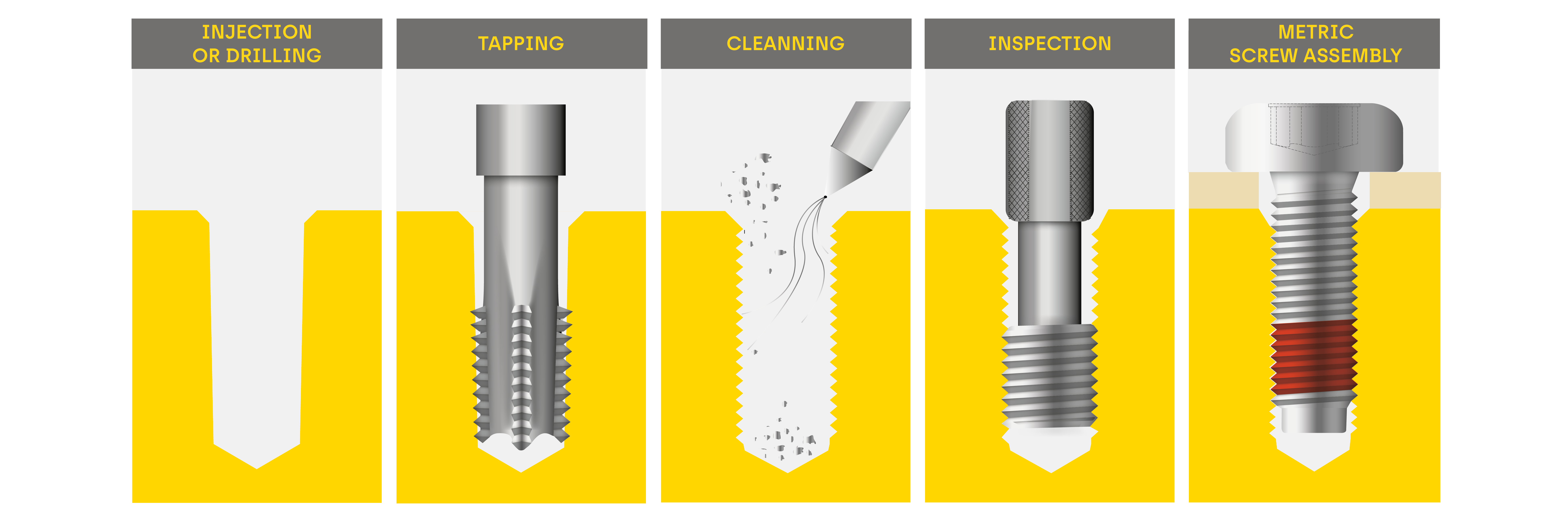

Find below an example listing the operations that are needed to install a machine screw and TAPTITE 2000® screw. A good joint design allows TAPTITE 2000® screw to achieve significant cost savings in any assembly:

Assembly with Metric screw

Assembly with TAPTITE 2000® screw

Benefits of using TAPTITE 2000® thread forming screws

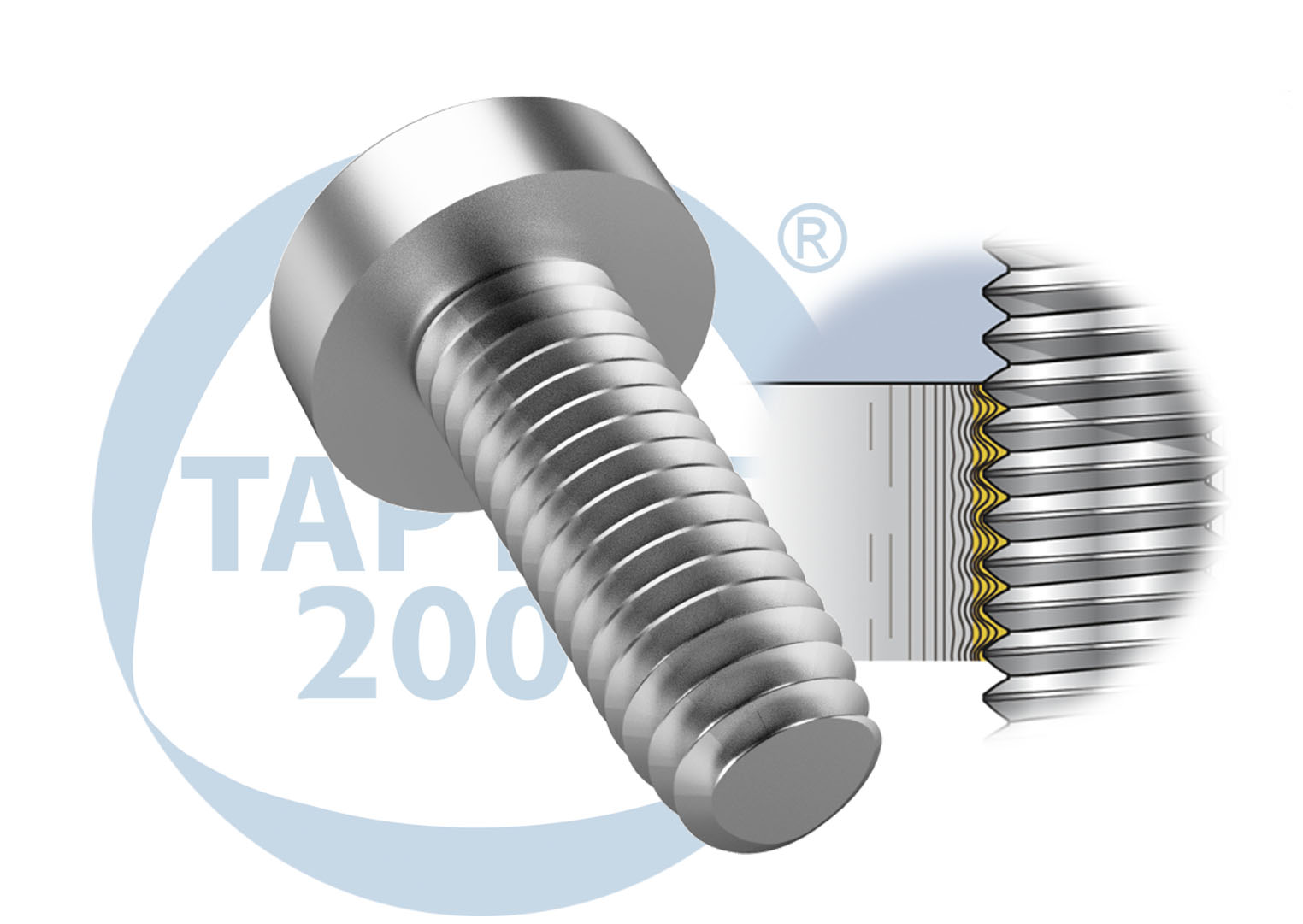

- TRILOBULAR® cross-section geometry of TAPTITTE 2000® screws provides low and uniform threading torque and increased stripping-to-drive ratio, which improves assembly efficiency and reduces assembly costs.

- Its excellent axial alignment in core hole requires low axial end load.

- High pull-out and stripping resistance. TAPTITE 2000® screws roll-forms high strength internal threads, no chips or burrs are produced during lamination.

- It allows a higher assembly torque, transmitting higher clamping to the assembly and reducing risk of stripping.

- As it's a thread rolling screws, it eliminates cross-threading problems and scrap and repair associated expenses.

- High prevailing torque allows superior resistance to vibration loosening eliminates the need of lock washers and/or adhesive patches.

Test TAPTITE 2000® screw in your assemblies.

Request Samples