- Cost-effective solutions for assemblies

- Solving your fastening problems

- Torque curve analysis for assembly

- Clamping force in plastic assemblies

- Magnesium assemblies fastening solutions

- Screw technology catalogues

Clamping force in plastic assemblies

Clamping force between the parts assures the assembly and it's the main parameter which determines the mechanical properties of the application.

Applying a higher torque will not always result in a higher clamping force. There are many other factors that determine the clamping capacity of a particular screw class:

Tightening torque: this is the torsion force applied on the screw, and the main responsible for its clamping force.

Coating friction coefficient: the greater the friction coefficient, the lesser clamping force will be obtained from the input torque.

Recess efficiency: the recess transmits the input torque from the screwdriver to the screw. Highly efficient recess will allow a better torque transmission and consequently, a higher clamping strength of the assembly.

TORX Plus® recess guarantees an optimal assembly torque transmission, providing higher clamping force than Philips or Pozidrive recesses.

Thread geometry: thread design also affects the ratio between torque and clamping force. Generally, a finer pitch increases clamping force if the resulting rise of friction doesn’t overcome that increase.

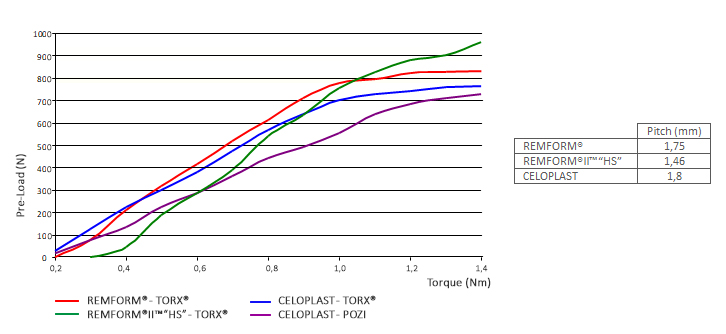

Effect of the thread and recess geometries on the clamping force.

The following curves show the effect of thread geometry (pitch) and recess type on Pre-Load force during the insertion process of screws diameter 4mm on plastic part PA66 + 15%GF, length of engagement of 6 mm.

The methods to check the clamping force are complex, so we normally verify torque values to validate each application. The input torque does not provide a quantitative indicator of the assembly’s properties, but a qualitative approach to the tightening process of the assembly elements.

New convenient and accurate techniques to measure clamping loads are currently being developed. CELO’s engineering laboratory is perfectly equipped with the necessary clamp load cells that allows us to relate torque and clamping force and also to evaluate the creeping in effect in plastic assemblies.

Please, contact us for further information.