CELO, global industrial fasteners and screw manufacturer

CELO, global industrial fasteners and screw manufacturer

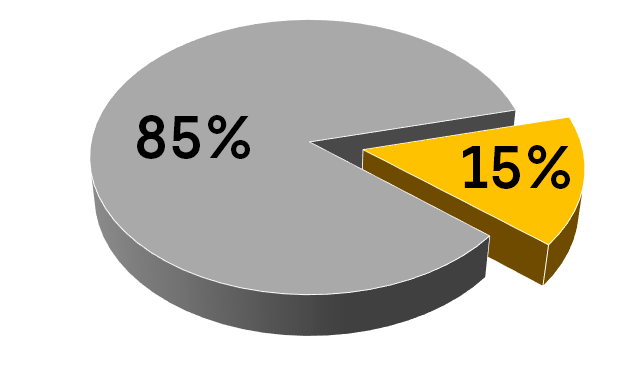

On average, when fastening machine screws in metal assemblies, screw represents only 15% of the total in-place cost. The remaining 85% corresponds to tapping operations, cleaning oil and chips, usage of additional elements to prevent vibration loosening and cross-threading, labor expenses, ...

All of these elements are known as "BIG 85™".

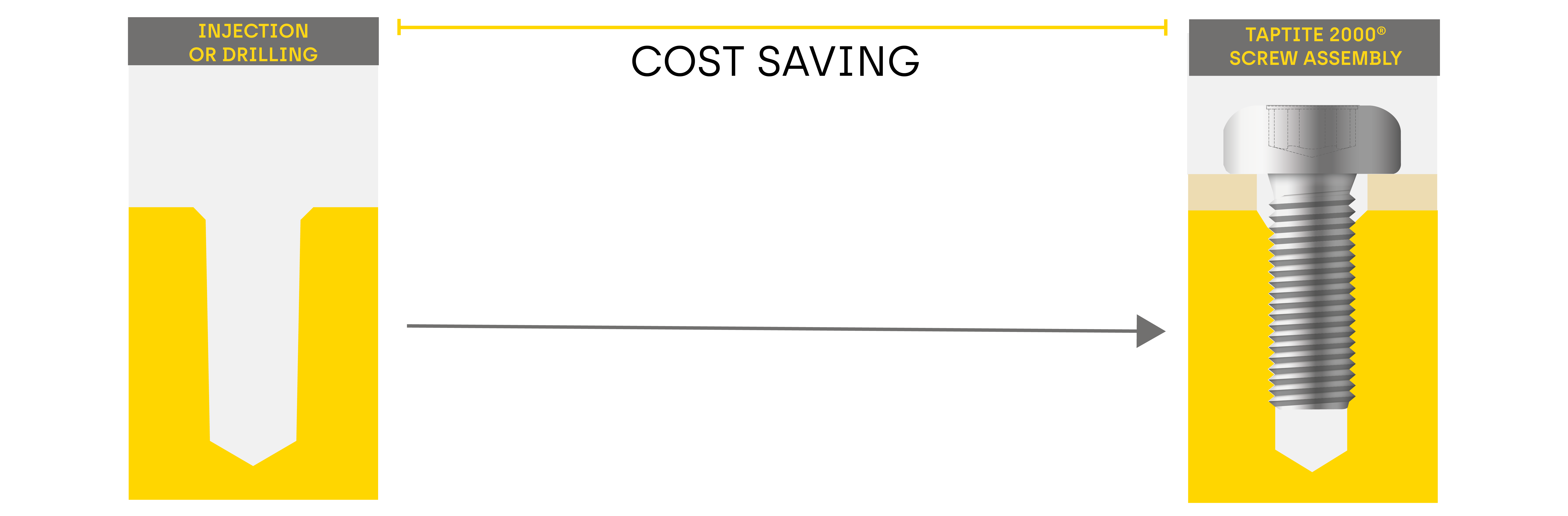

Buying cheaper screws will not save you a lot. Screws represent just 15% of the total cost. The challenge is to reduce this "BIG 85™" and TAPTITE 2000® screw is the best solution to achieve this goal.

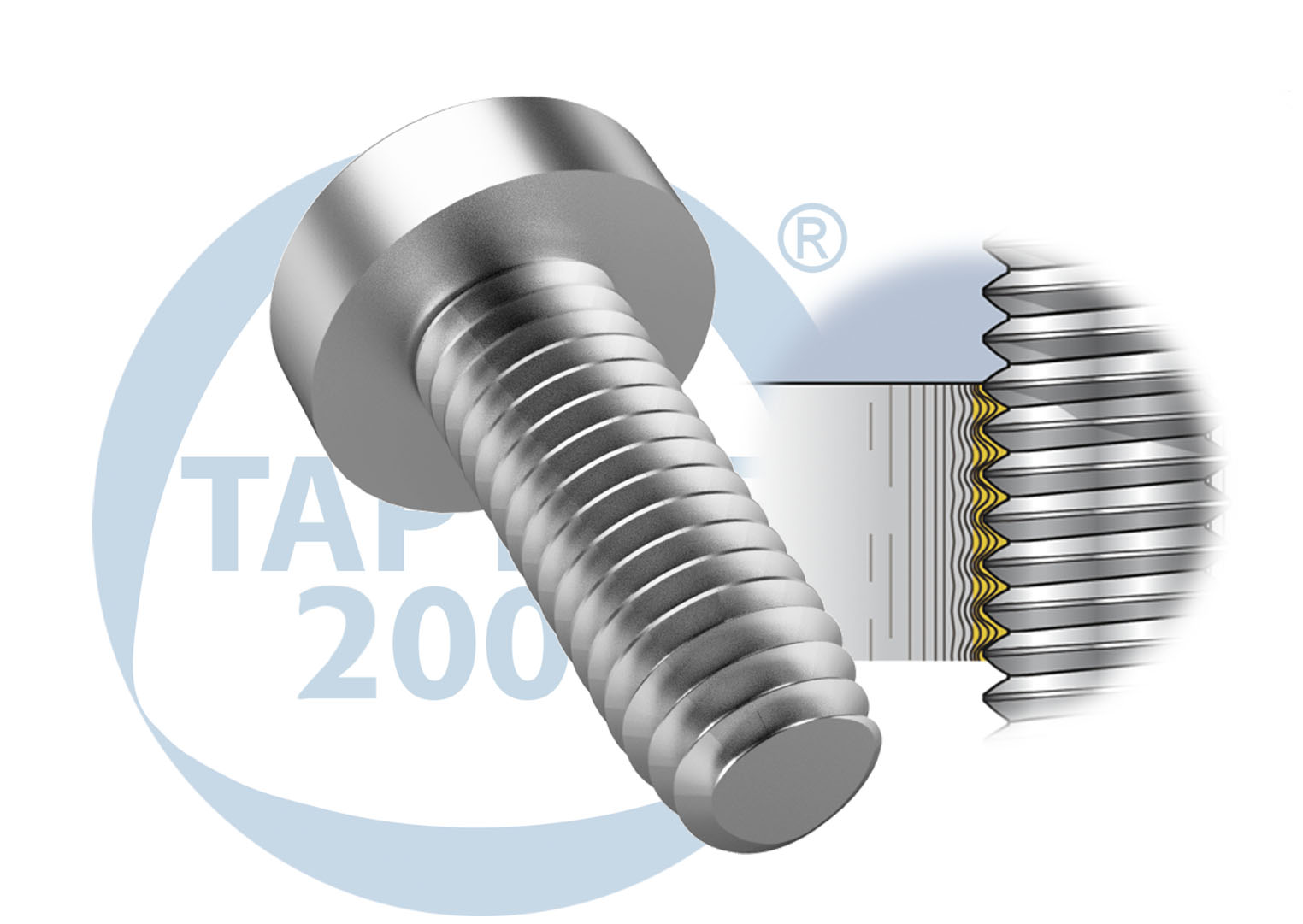

TAPTITE 2000® thread forming screws provide assemblies with excellent mechanical properties and ergonomics as well as significant cost savings in the overall assembly cost, that's "BIG 85™":

Contact us and start saving costs as soon as possible!

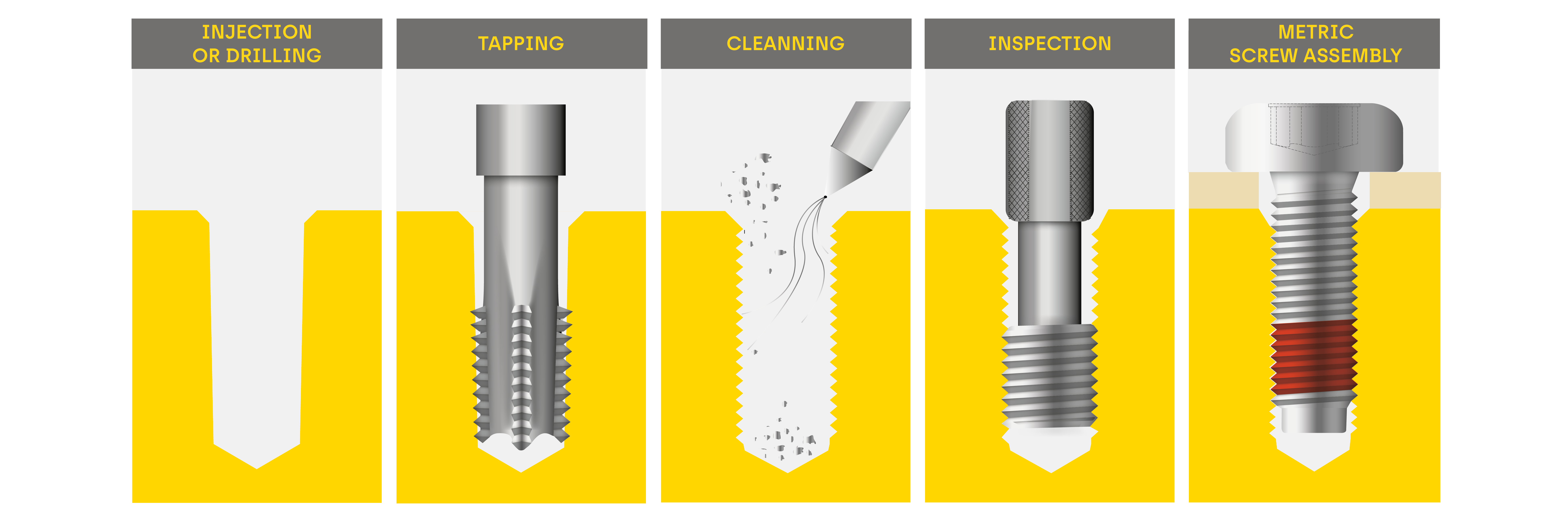

Find below an example listing the operations that are needed to install a machine screw and TAPTITE 2000® screw. A good joint design allows TAPTITE 2000® screw to achieve significant cost savings in any assembly:

Test TAPTITE 2000® screw in your assemblies.