CELO, global industrial fasteners and screw manufacturer

REMFORM® II F™ screw

When to choose REMFORM® II F™ screw?

REMFORM® II F™ thread forming screw for plastics is the best solution for the assembly of very hard materials such as glass fiber-reinforced plastics, thermoset materials, phenolic resin,...

REMFORM® II F™ screw is also recommended for the assembly of thermoplastics where the length of engagement is lower than optimal.

How does it work?

- REMFORM® II F™ screws form their own threads into very hard materials.

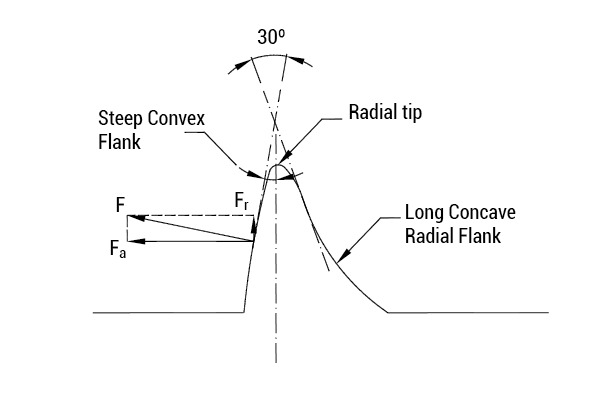

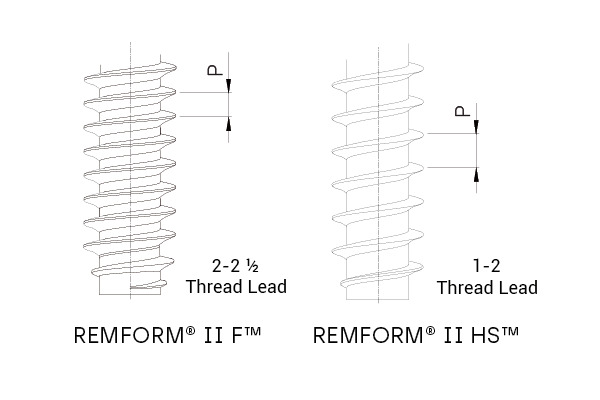

- REMFORM® II F™ thread employs the Asymmetric thread design of REMFORM® II F™ but increased core diameter and smaller thread pitch, adapted to the assembly requirements of materials with low ductility.

- The smaller pitch of REMFORM® II F™ screws increases the number of threads along the shank of the screws, increasing pull-out and vibrational loosening resistance.

REMFORM® II F™ screw benefits

- The smaller pitch of REMFORM® II F™ thread increases the contact along the shank of the screw, improving pull-out resistance of assemblies on very hard plastics and thermoset materials.

- The low radial forces minimize the risk of overstressing and cracking of the plastic.

- It allows a shorter engagement depth, ensuring an improved clamping force of the assembly.

Downloads & Services

Screw design specifications

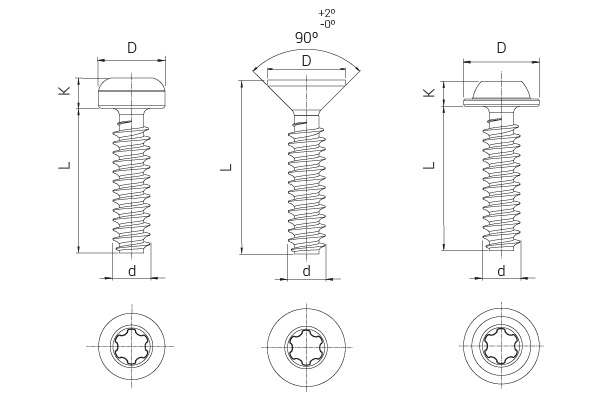

We produce customized REMFORM® II F™ screws to fit your exact requirements. To improve their functionality, REMFORM® II F™ screws can be produced under different head designs, recess, dimensions and coating configuration.

For further information on the options available, please contact our application engineers.

Additionally, we offer a wide range of REMFORM® II F™ screws in stock for immediate delivery.

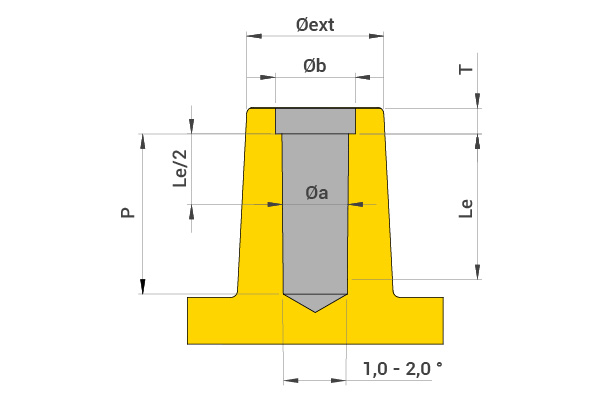

Boss Design Guidelines

In order to ensure a safe installation and stable clamping force, it's relevant to pay attention to the boss design.

The recommended dimensions for core hole diameter and length of engagement are available at Design Guidelines.

Markets

Motors and pumps

Automotive

Electronics

Electric cabinets

Lighting

Furniture