CELO, global industrial fasteners and screw manufacturer

PCB screws

When to choose PCB screw?

PCB plastic screws have been especially designed to solve problems of:

- Assembly of thin hard plastics.

- Assembly of components on printed circuit boards (PCBs).

How does it work?

When thin hard plastic elements are assembled with standard screws for plastic, the length of engagement is not long enough to avoid stripping and to ensure the correct pull-out resistance of the assembly.

PCB screws solve stripping and bursting problems, offering great opportunities to reduce assembly costs.

Benefits

For the assembly of hard plastics thin elements:

- Reduced boss bursting risk.

- Improved resistance to stripping.

- Allow for a higher assembly torque.

For the assembly on PCBs:

- The head of the screw is set directly on the connector, avoiding interferences with the tracks.

- Directly fixed to avoid damaging the PCB.

- Higher resistance to vibration loosening.

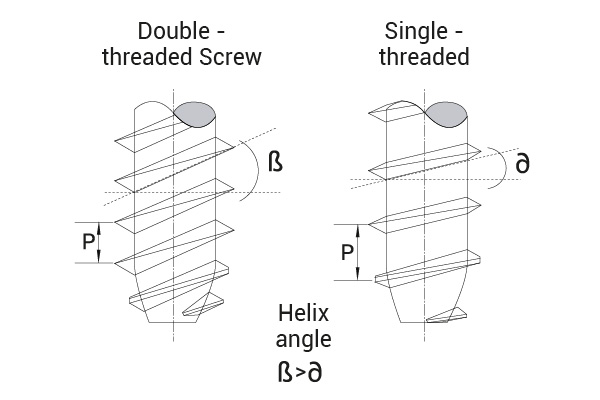

- Twin-lead thread increases threading speed.

Downloads & Services

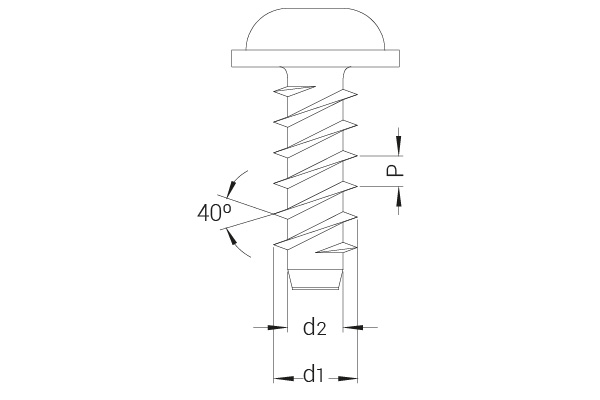

Screw design specifications

We produce customized PCB screws to fit your exact requirements. To improve their functionality, PCB screws can be produced with different head types, recess, dimensions and coating configuration.

For further information on options available and boss design recommendation, please contact our application engineers.

Markets

Electric material

Automotive

Household appliances

Electronics