CELO, global industrial fasteners and screw manufacturer

REMFORM® II HS™ screw

When to choose REMFORM® II HS™ screw?

REMFORM® II HS™ (High Strength) screws are recommended for the direct assembly on high strength or fiber-reinforced plastics in applications that require:

- High clamping force.

- High pull-out resistance.

- High resistance to vibration loosening.

The improvements of thread forming REMFORM® II HS™ screws result in a more resistant, safe and optimized assembly on fiber-reinforced thermoplastic with great opportunities for cost reduction.

How does it work?

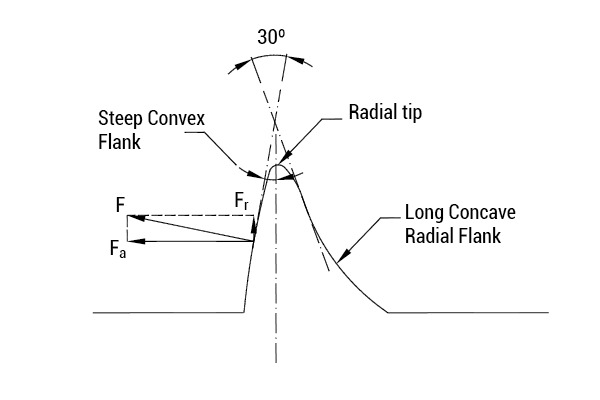

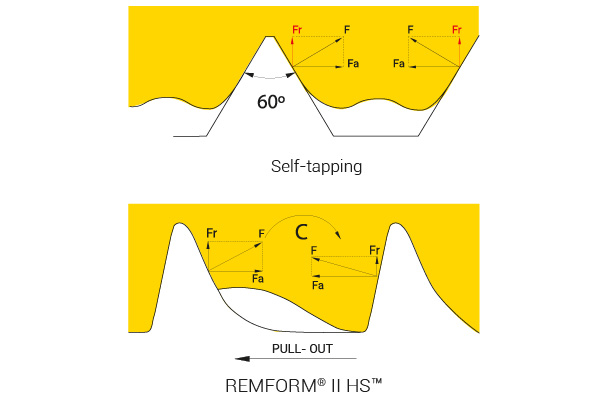

REMFORM® II HS™ screws form their own threads and create a strong nut member into reinforced plastics.

- Minimal radial tension during thread forming minimize the risk of overstressing the plastic. It allows for bosses with thinner walls.

- Its optimized thread design provides excellent material contact which results in high resistance to stripping and vibrational loosening resistance.

- It allows for a reduction in screw diameter and/or length.

REMFORM® II HS™ screw benefits

- The optimized design of its asymmetrical thread provides a more ergonomic assembly and increases resistance to pull-out forces, vibration loosening and stripping.

- The low radial forces minimize the risk of overstressing and cracking of the plastic. It allows for bosses with less external diameter, which offers great opportunities for cost reduction.

- High torsional strength of REMFORM® II HS™ fasteners ensures a high torque failure, which is an advantage when the fastener is used with high strength or fiber-reinforced thermoplastic.

- It allows a higher assembly torque and the possibility to work with deeper assemblies without increasing the screw diameter.

Downloads & Services

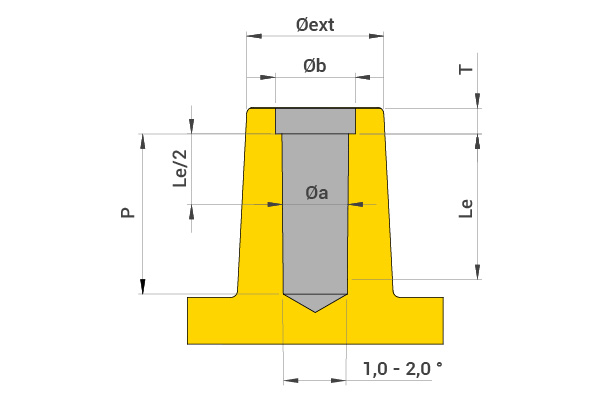

Screw design specifications

We produce customized REMFORM® II HS™ screws to fit your exact requirements. To improve their functionality, REMFORM® II HS™ screws can be produced under different head designs, recess, dimensions and coating configuration.

For further information on the options available, please contact our application engineers.

Additionally, we offer a wide range of REMFORM® II HS™ screws in stock for immediate delivery.

Products in stock

HS81PA

REMFORM® II HS™ Zinc plated screw, Pan head TORX PLUS® AUTOSERT®

Go to the product

HS82PA

REMFORM® II HS™ Zinc plated screw, Countersunk head TORX PLUS® AUTOSERT®

Go to the product

HSX81PA

REMFORM® II HS™ Zinc plated screw, Pan head TORX PLUS® AUTOSERT®, INOX A2

Go to the product

HS87PA

REMFORM® II HS™ Zinc plated screw, Pan head flange TORX PLUS® AUTOSERT®

Go to the productBoss Design Guidelines

In order to ensure a safe installation and stable clamping force, it's relevant to pay attention to the boss design.

The recommended dimensions for core hole diameter and length of engagement are available at Design Guidelines.