CELO, global industrial fasteners and screw manufacturer

MAThread® screw

When to choose MAThread® screw?

MAThread® point is the solution to cross-threading problems during assembly processes. Machine screws with MAThread® point provides great cost saving opportunities by reducing screw insertion time and eliminating costs derived from downtime, rework and scrap associated to cross-threading.

MAThread® and MATpoint® are registered in product standards of many automotive OEMs including General Motors, Volkswagen, Daimler-Benz and their suppliers.

In addition to automotive, household appliances, manufacturers in electronics, telecom and electric sectors are taking advantage from this thread technology.

How does it work?

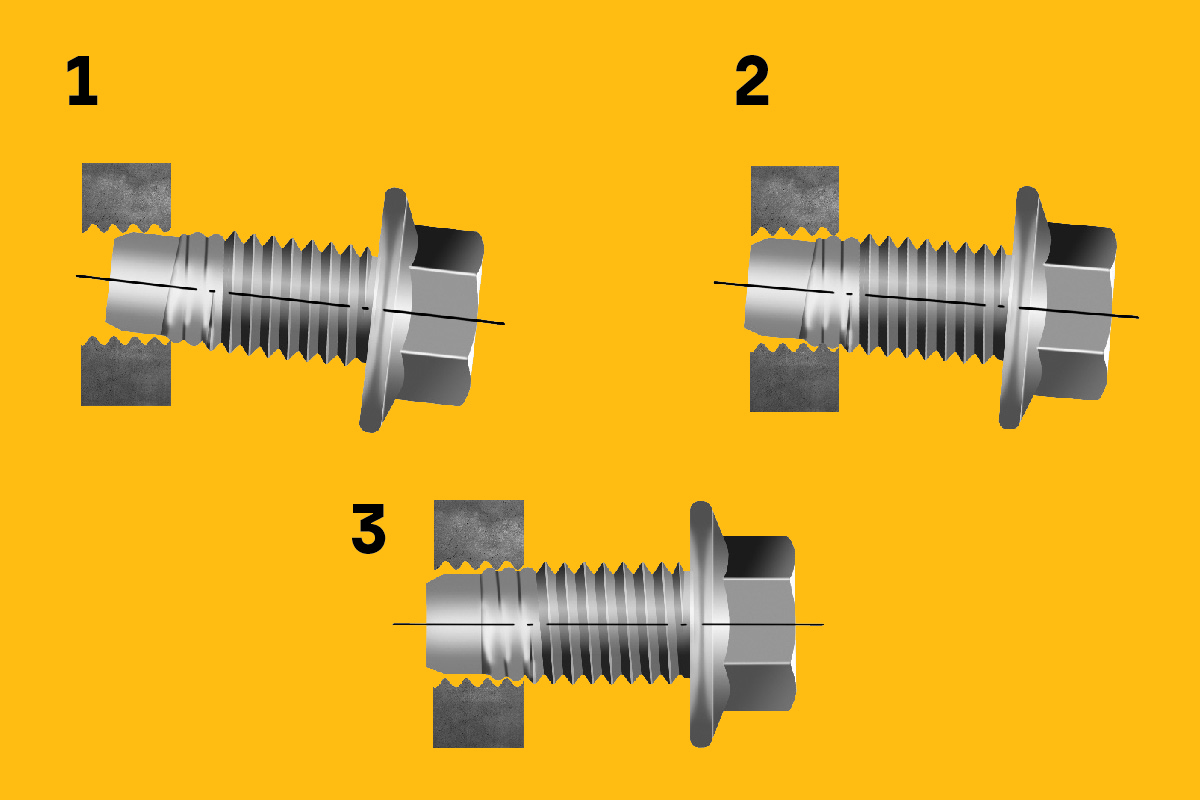

1. There's helix misalignment.

2. MAThread® point aligns the screw to fit into nut memeber. It eliminates the risk of cross-threading.

3. Threads drive normally into the nut eliminating the risk of downtime and rework.

MAThread® point screws and its different variants are recommended for assemblies into:

- Nuts, tapped holes and inserts in full automated assembly lines.

- Applications susceptible to cross-threading problems.

Benefits

- Reduces the cost of assembly: MAThread® point allows an easy and rapis insertion without reducing the installation speed.

- Avoid cross-threading and blocking problems.

- MAThread® performance is unaffected by installation speed.

Downloads & Services

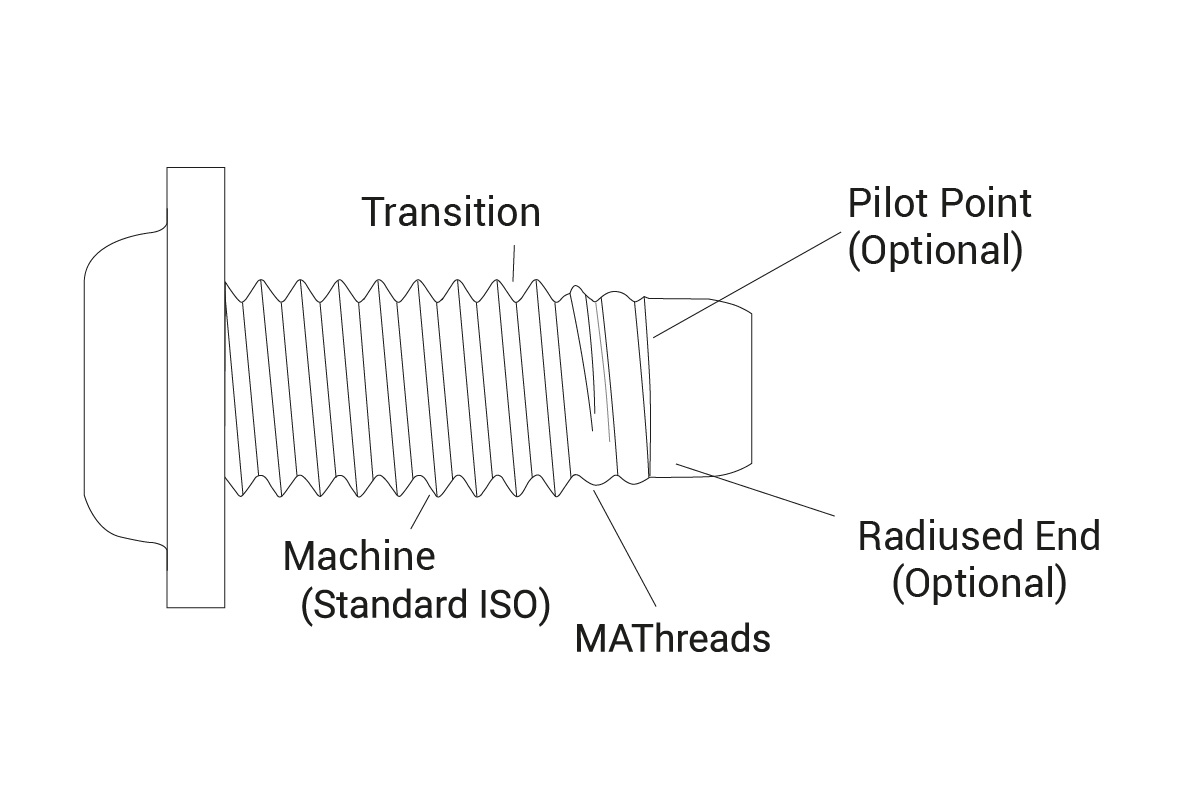

Screw design specifications

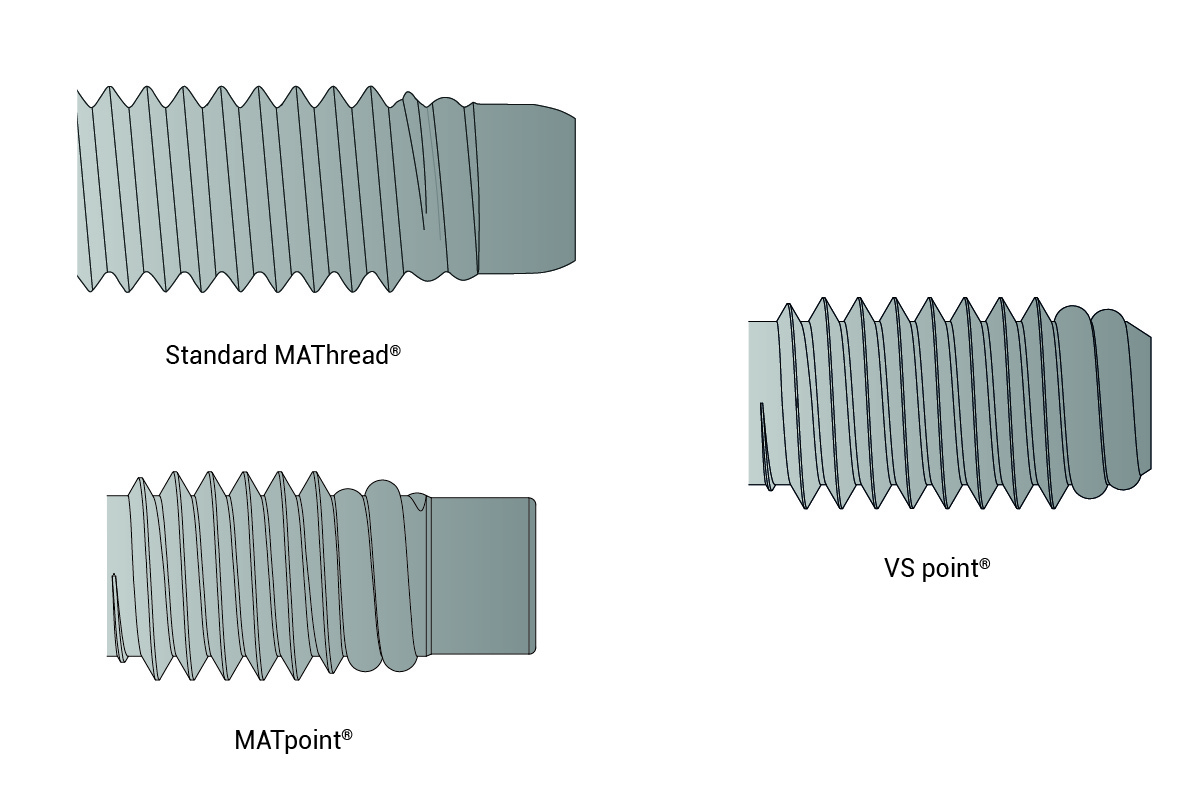

We produce MAThread® screws on special demand to fit your exact requirements. There are different point designs depending on the application requirements:

'P' Point MAThread® for applications in which point length is not a problem.

MATPOINT® is compatible with most of the applications, it absorbs misalignments up to 12º.

VS (Very Short) MATpoint® is ideal for application with limited length of engagement, it absorbs misalignments up to 7º.

For further information on options available and hole configuration, please contact our application engineers.