CELO, global industrial fasteners and screw manufacturer

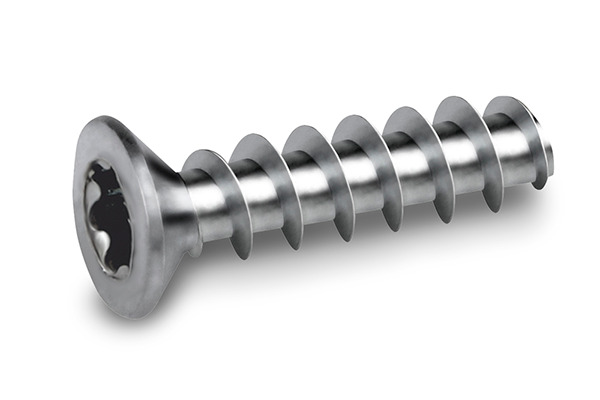

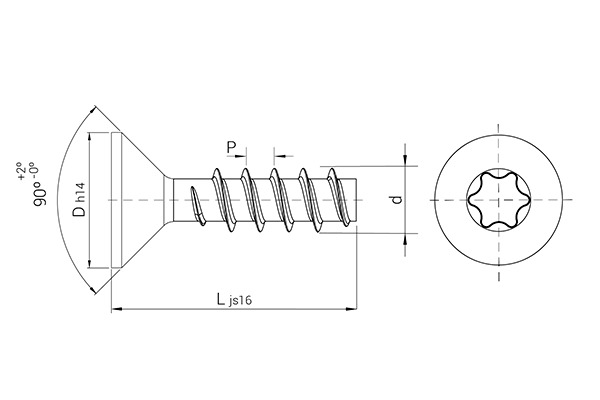

CELOspArk® Zinc plated screw, Countersunk head TORX®

For an optimal direct assembly of ductile plastics.

Product overview

CELOspArk® screw with an improved 30º thread design solves the problem of boss bursting and provides greater safety in the assembly process into ductile plastics.

It provides lower thread forming torque for a more ergonomic assembly and higher pull-out, stripping and vibrational loosening resistant .

Apart from the reference available in stock, we produce customized screws under different dimensions and coating configurations.

List of references

Filters

Screw diameter (mm)

Close

3.0

3.5

4.0

Screw length L (mm)

Close

6

8

12

16

10

Head diameter D (mm)

Close

6.00

7.00

8.00

Recess

Close

TORX® T10

TORX® T15

TORX® T20

Reference

J

d

36SP82T

38SP82T

312SP82T

316SP82T

3510SP82T

3512SP82T

412SP82T

416SP82T

Screw diameter (mm)

J

d

3.0

3.0

3.0

3.0

3.5

3.5

4.0

4.0

Screw length L (mm)

J

d

6

8

12

16

10

12

12

16

Head diameter D (mm)

J

d

6.00

6.00

6.00

6.00

7.00

7.00

8.00

8.00

Recess

J

d

TORX® T10

TORX® T10

TORX® T10

TORX® T10

TORX® T15

TORX® T15

TORX® T20

TORX® T20

8 / 8 references are shown

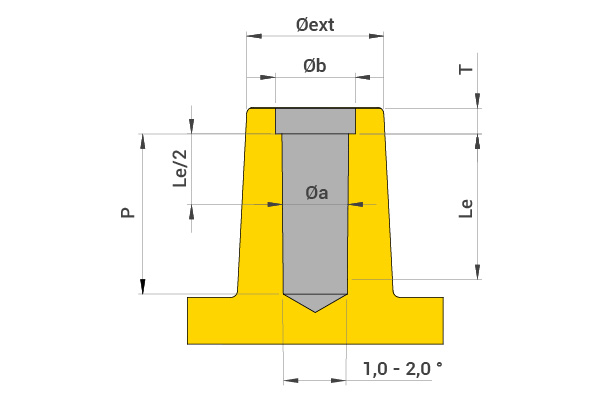

Hole parameters calculator

In order to ensure a safe installation and stable clamping force, it's relevant to pay attention to the boss design. The recommended dimensions for core hole diameter and length of engagement are available at Design Guidelines.

Go to Design Guidelines

Applications

CELOspArk® screw is recommended for the assembly of ductile plastics. The design of CELOspArk® screws meet the standards of a large number of electric material, electronics and automotive manufacturers (i.e. VW 603 62).

Do you have any questions about this product?

Request more info